24+ How Do You Calculate The Depth Of A Spot Drill info

How do you calculate the depth of a spot drill. But they do that so as not to break through and intersecting hole on the part. When drilling a pilot hole make the diameter a little larger than the web thickness of the big twist drill youre clearing the way for. The actual cut dimension will probably be more after cutting due to the countersink point on the tool is usually not perfect causing the tool to cut deeper. If you decide to go with 90 spot drills the spot depth is 12 the drill. You simply divide the diameter of the spot-drilled hole. A spot drill has a 90-degree point angle which makes it easy to calculate the depth of a hole to be spot-drilled. Unfortunately if you do a simple calculation you find that these three specifications tell you different things - the pullback capacity is far greater than the hoist pull capacity and neither relate to the recommended depth. Calculating depths versus diameters for various sizes The Calculator covers spot drills center drills. If you have drilled a 025 diameter hole and want a 0031 chamfer on the hole the diameter to be spot drilled will be 0312. Fear not our G-Wizard Calculator has some awesome tools to help. Make sure your calculator is set to degree mode. Lay the drill bit down beside the fastener that you intend to drive to determine the fasteners length.

Depth Drill Width 03 So for a250 hole your spot drilling depth is 0075. Ideally the spot drill diameter should be about 70 of the size of your final drill diameter. Well depth 10000 ft. The pullback capacity the hoist pull capacity and the recommended depth capacity in terms of a range of standard wireline drill rod sizes. How do you calculate the depth of a spot drill You can increase tool life considerably if you spot drill a dimple 5 larger than the micro-drills diameter. So if you would need 1 full diameter hole depth with a 5 drill you would drill 1150 deep. Using a larger angle drill will allow the drill to find the correct location by guiding the tip of the drill to the center. If you have drilled a 025 diameter hole and want a 0031 chamfer on the hole the diameter to be spot drilled will be 0312. You simply divide the diameter of the spot-drilled hole. For a 118 degree drill tip use the formula 31tan radius. Manufacturers provide three specifications. If youre going to do all these cool tricks with a spot drill youre going to need to do some geometry calculations. If the outer diameter of a carbide drill were to contact the workpiece first the tool could chip.

When To Use A Spot Drill 7 Useful Tips And Techniques Cnccookbook Be A Better Cnc Er

When To Use A Spot Drill 7 Useful Tips And Techniques Cnccookbook Be A Better Cnc Er

How do you calculate the depth of a spot drill Calculating the depth to feed a center drill spot drill or countersink to machine a specific chamfer diameter on the face of a part is one of those recurring time-wasters that every programmer and machinist is familiar with.

How do you calculate the depth of a spot drill. This would damage the workpiece and result in a defective tool. Depends a lot on how the print is drawn here at work it is the total depth including point. Leave 24 bbl in the drill string.

The spot-drill depth 0156 is half of this. Often we use a 150 drill point to flatten the hole out for great tap chip clearance. A spot drill has a 90-degree point angle which makes it easy to calculate the depth of a hole to be spot-drilled.

Check the item you want to calculate input values in the two boxes and then press the Calculate button. To determine the ideal minimum drill depth start with the basic rule. What Happens if I Use a Spot Drill with an Improper Angle.

The tap drill depth should be at least one thread or one pitch beyond the chamfer of the tap. When youre drilling more than 7 x Drill Diameter in depth it can be helpful to do a small pilot hole to a depth of 2 x Drill Diameter. G-Wizard will automatically offer this tip when appropriate.

For a 5 drill the equation would be 31tan 25150. Spot drilling is not recommended in hardened steels. It even handles countersinks with a flat on the end.

The drill depth calculator turns this into a few seconds work. The spot drill point angle should be greater than or less than the final drills point angle. So be sure to adjust your numbers so as not to cut too deep.

This way you can butt the tip of the drill bit to the underside of the screw head accounting for the full depth of the shank. Countersink Calculator This will calculate the z depth to enter for a given diameter and angle of countersink. However due to the flat on the drill this will leave a chamfer of 0025.

With a 118 degree spot the depth calculation is easy. Click to see full answer. Use the following data to spot an oil based pill around the drill collars plus 200 ft optional above the collars.

Spot drill chamfering a hole. Position them so theyre pointing in opposite directions though. For example if you are using a 38-in spot drill to leave a 0025 chamfer on a 025-in hole the calculated depth would be 0150 02502 0025.

How do you calculate the depth of a spot drill For example if you are using a 38-in spot drill to leave a 0025 chamfer on a 025-in hole the calculated depth would be 0150 02502 0025.

How do you calculate the depth of a spot drill. Position them so theyre pointing in opposite directions though. Spot drill chamfering a hole. Use the following data to spot an oil based pill around the drill collars plus 200 ft optional above the collars. Click to see full answer. With a 118 degree spot the depth calculation is easy. However due to the flat on the drill this will leave a chamfer of 0025. Countersink Calculator This will calculate the z depth to enter for a given diameter and angle of countersink. This way you can butt the tip of the drill bit to the underside of the screw head accounting for the full depth of the shank. So be sure to adjust your numbers so as not to cut too deep. The spot drill point angle should be greater than or less than the final drills point angle. The drill depth calculator turns this into a few seconds work.

It even handles countersinks with a flat on the end. Spot drilling is not recommended in hardened steels. How do you calculate the depth of a spot drill For a 5 drill the equation would be 31tan 25150. G-Wizard will automatically offer this tip when appropriate. When youre drilling more than 7 x Drill Diameter in depth it can be helpful to do a small pilot hole to a depth of 2 x Drill Diameter. The tap drill depth should be at least one thread or one pitch beyond the chamfer of the tap. What Happens if I Use a Spot Drill with an Improper Angle. To determine the ideal minimum drill depth start with the basic rule. Check the item you want to calculate input values in the two boxes and then press the Calculate button. A spot drill has a 90-degree point angle which makes it easy to calculate the depth of a hole to be spot-drilled. Often we use a 150 drill point to flatten the hole out for great tap chip clearance.

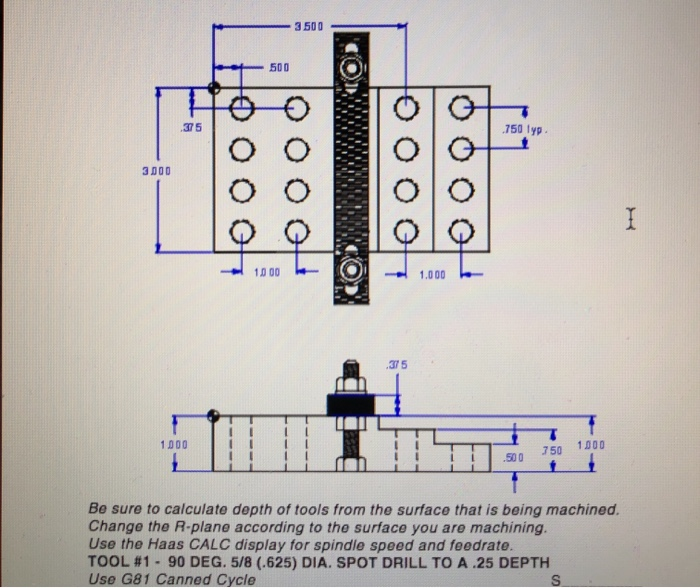

Canned Cycle Exercise 2 Hooooh Ho000 Oooo Be Sure Chegg Com

Canned Cycle Exercise 2 Hooooh Ho000 Oooo Be Sure Chegg Com

The spot-drill depth 0156 is half of this. Leave 24 bbl in the drill string. Depends a lot on how the print is drawn here at work it is the total depth including point. This would damage the workpiece and result in a defective tool. How do you calculate the depth of a spot drill.